VACIS® IR6500

Integrated Railcar Inspection System

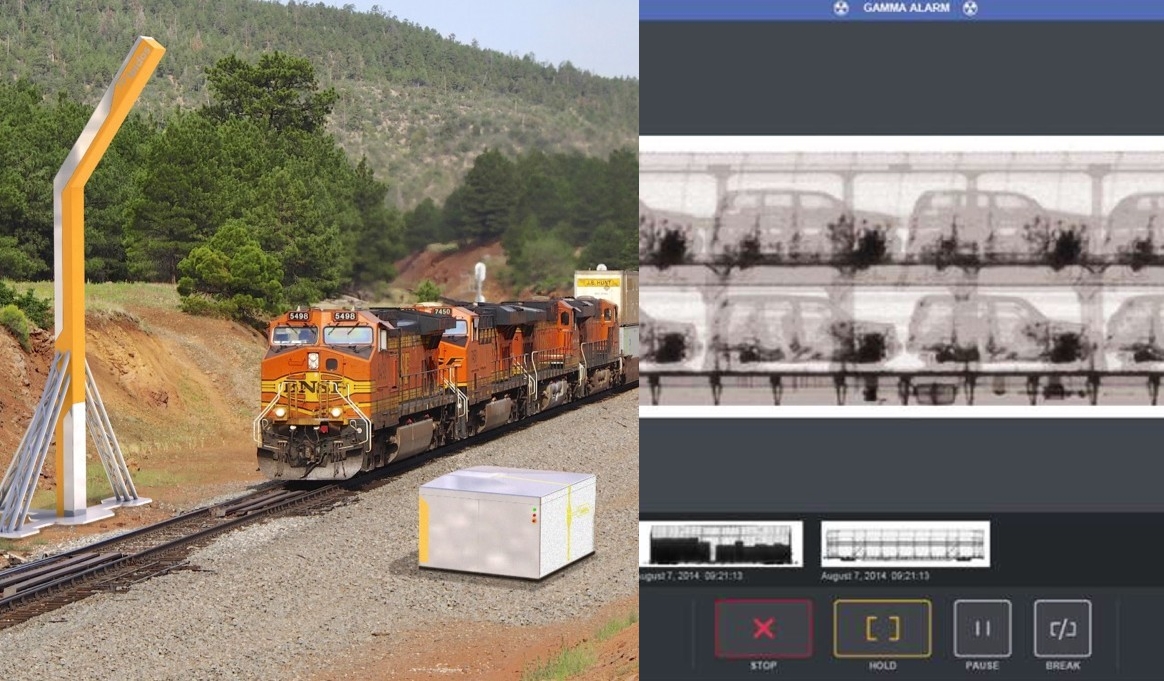

High-energy X-ray imaging, radiation scanning, and RFID for railcars: a fast, integrated inspection solution for security and commerce

The VACIS IR6500 integrated railcar inspection system is a powerful, practical solution for high-volume scanning of railcars and containers on rail.

The VACIS IR6500 system uses high-energy X-ray technology to produce detailed images of railcar and container contents, including dual-energy material discrimination of organic threats. At the same time, the system can scan each railcar or container to detect, locate and categorize nuclear material. Its radio frequency identification (RFID) tag reader can identify each railcar.

And its database component integrates and displays scanning images and data on demand. Built for high throughput, the system can scan two one-mile-long trains per hour. With its small footprint and low radiation dose, the system can be implemented in very limited space. And by revealing weapons, nuclear material, and other contraband, the system can greatly reduce the need for costly manual inspections.

A POWERFUL SCANNING SOLUTION FOR RAIL CARGO

The VACIS IR6500 system combines three powerful scanning technologies in a fast, compact unit.

- High-energy X-ray imaging. The VACIS IR6500 system can reveal threats and contraband through more than ten inches of steel. And its low radiation dose increases safety and reduces space requirements.

- Radiation scanning option. The system can detect, locate, and optionally categorize even heavily shielded special nuclear material with a false alarm rate of less than 1 in 10,000 — meeting or exceeding the American National Standards Institute’s challenging N42.35-2006 standard.

- RFID option. The system can automatically identify railcars as they are scanned. The system reads standard Association of American Railroads S-918 RFID tags.

The system quickly integrates the scanning images and data for each railcar. Security personnel can review the images and data at any time.

FAST AND COMPACT

The system can scan two one-mile-long trains per hour. And with its low radiation dose, it can be implemented in a space only slightly larger than the system itself.

NEW SYSTEMS OR UPGRADES TO EXISTING SYSTEMS

In addition to new installations, the system can be provided as an upgrade for legacy Leidos gamma-ray Railroad VACIS systems, utilizing existing civil works and infrastructure where possible to lower costs, ease installation, and greatly improve performance.

LEIDOS – A WORLD LEADER

Leidos has provided hundreds of VACIS systems for customs, security, and military applications around the world. Every VACIS system is available with our global installation, training, maintenance, and 24/7/365 technical support.

BENEFITS

- High-energy X-ray imaging with material discrimination

- Low radiation dose

- Small operating footprint

- Integrated radiation scanning and equipment identification options

- Integrated display — X-ray image and radiation scan results integrated into a single transaction

- Available for new installations or as an upgrade for legacy Leidos gamma-ray Railroad VACIS systems

CAPABILITIES

- High-energy X-ray imaging

- Dual-energy material discrimination

- Sensitive radiation scanning option with available categorization to automatically exclude harmless naturally occurring radioactive material

- RFID railcar identification option

- High throughput — two one-mile- long trains per hour

- Fast data integration and display

- Small operating space with no external shielding

- Low radiation dose for safety and small footprint