VACIS® IP6500

Integrated Cargo Inspection System

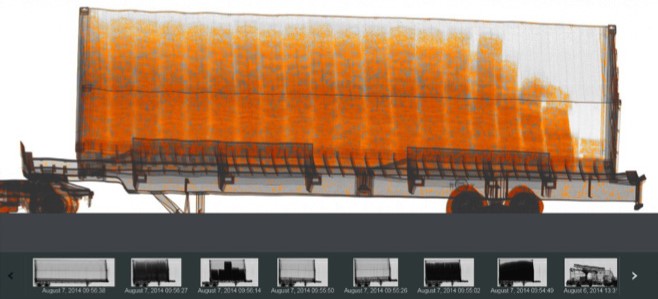

X-ray imaging and full-time material discrimination of cargo in a modular, compact, easy-to-deploy configuration

The VACIS IP6500 integrated inspection system is a powerful, practical solution for inspecting cargo containers in high-volume operations. The system can scan 150 or more containers per hour, from roof to axles.

The system’s high-energy X-ray provides detailed images, even through heavy shielding, and can distinguish organic threats from inorganic material. Its radiation sensing system can detect, locate and categorize nuclear threats. Its optical character recognition (OCR) system can identify containers as they are scanned. And its searchable database component integrates and delivers images and data on demand.

The VACIS IP6500 system requires no civil works—it can be installed directly on an existing concrete or asphalt pad—and its low radiation dose allows operation in extremely small spaces with absolutely no need for shield walls or containment buildings.

Compact, powerful, and effective, the VACIS IP6500 system is the choice for port operators, customs organizations, and military and law enforcement worldwide.

A POWERFUL, PRACTICAL SCANNING SOLUTION

The VACIS IP6500 system combines powerful scanning technologies in a fast, compact unit.

- High-energy X-ray imaging. The system can reveal threats and contraband through a foot of steel. And its low radiation dose increases safety and dramatically reduces space requirements.

- Full-time dual-energy material discrimination. The system distinguishes light, organic material from dense, inorganic material.

- Radiation sensing option. The system can detect and locate even heavily shielded special nuclear material (SNM) with a false alarm rate of less than 1 in 10,000 — meeting or exceeding the American National Standards Institute’s challenging N42.35-2006 standard. An advanced option also categorizes the nature of the threat, greatly reducing secondary inspection requirements.

- Container identification option. The system’s OCR component automatically identifies containers as they are scanned.

The system quickly integrates the scanning images and data for each vehicle. Security personnel can review the images and data at any time.

FAST AND COMPACT

The VACIS IP6500 system can scan more than 150 vehicles per hour as they drive through without stopping. With a typical operating footprint of just 8.5 by 3 meters—barely larger than the system itself—the system is perfect for use in tight spaces.

BENEFITS

- Automatically scans cargo only—never drivers

- Full-time dual-energy material discrimination

- Requires no civil works, and modular design speeds installation

- Very low radiation dose to vehicle occupants and bystanders

- Extremely small operating area with no added shielding required

- High throughput drive-through operation

- Modern, intuitive operating software is easy to use

CAPABILITIES

- High-energy X-ray imaging

- Full-time dual-energy material discrimination

- Installs quickly with no civil works required

- High throughput—more than 150 containers per hour

- Available radiation sensing with very low false alarm rate

- Available OCR container identification

- Fast data integration and display

- Extremely small operating space, no added shielding required

- Low radiation dose for safety and small size